- Home / About us

Z Fever Logon

Zfever Video

Z Fever Map

Z-Fever / Fever Racing: 4715 N Clark Ave, Tampa, FL (813) 877-7600

- Services

- Dyno / Results

- Technical Documents

- Gallery / Media

- Online Stores

- Monthly Specials

VQ35DE Swap / 240SX (and other cars)

In 2003, Nissan developed the 350Z. With it came a new engine format, the VQ35DE.

It is an all aluminum block V6 with aluminum heads. It has dual overhead cams and variable valve timing. This motor puts out 287hp at the flywheel at a max rpm of 7200. It has a completely linear power curve and propels the 350Z 0-60 in 5.4 seconds and turns the 0-1/4 mile in 14.1sec @ 101.0mph. Not bad for a car who’s curb weight is 3188-3347 lbs(coupe), 3445-3479 lbs(convertible).

Since its inception many tuners have had tweaked and tuned the 350Z into producing a lot more horsepower. Just adding a turbo kit to the VQ35 will increase horsepower by 150hp+. The VQ35 has proven itself to be one of the most popular engines for tuners to build because it is light, makes good horsepower, is very tunable, and sounds great under acceleration. This combination has led many people to try to utilize (swap) the VQ35DE engine in their car.

The 240SX is the most popular chassis currently being used by many who want to either drift, drag, or show. Many manufacturers have recognized the 240SX’s nimble yet stiff chassis and the combination or independent suspension and RWD make it ideal. There are many, many manufacturers that produce aftermarket performance upgrades for every part of the 240SX. Nearly every suspension component you can think of is available.

The VQ35DE motor fits nicely into the 240SX’s engine bay. It is about the same weight as the KA24DE 4cyl motor that came in the 240SX. The KA24DE uses a cast iron block which adds considerable weight. Here is a picture of the VQ35DE installed into a 240SX S13 chassis:

You can see how well it fits. We make a bolt-in kit to help you install the VQ35DE into either the 90-94 (S13) or the 96-98 (S14) 240SX chassis’. It consists of a remanufactured front X-member, a transmission mounting bracket, a shifter mounting bracket, and front sway bar spacers. With this kit the VQ35DE easily bolts into the 240SX like it was made for it. Here are some pics of these components:

This is the trans mounting bracket:

This is the shifter mounting bracket:

This is the engine X-member:

Installation of the engine will also require custom rubber motor mounts and a custom driveshaft. We can provide these for you also.

After the motor and trans are installed there are several challenges to overcome. You will need some sort of engine management system to operate the fuel system and the ignition system. The factory ECU that comes with the 350Z is very complex. I won’t spend a lot of time explaining all of it but in short, it is very difficult to use the factory ECU in a swap. The factory ECU works on a cannes system. It is linked to 4 different computers in the car as well as the ignition key itself. They all have to talk to each other in order for the car to run. If you were to “borrow” an ECU from a 350Z and install it into an IDENTICAL 350Z it would not start the car because the keys are all coded to that particular car and that ECU.

Also, the VQ35DE (like most cars today) use a “drive by wire” throttle assembly rather than a cable driven throttle body. It uses an electronic voltage signal from the throttle sender on the pedal assembly to send a signal through the ECU which then routes it to a step motor on the side of the throttle to open and close the throttle plate. We use a 75mm cable driven throttle body and make an adapter plate and pipe that bolt onto the upper plenum after removal of the OEM Nissan throttle body. You can then use the 240SX’s factory throttle cable. Here is a close up picture of our throttle pipe:

It utilizes a Ford Mustang Cobra TPS switch. You can buy those at you local auto parts store or direct from Ford. That’s where we buy the TPS pigtail harness.

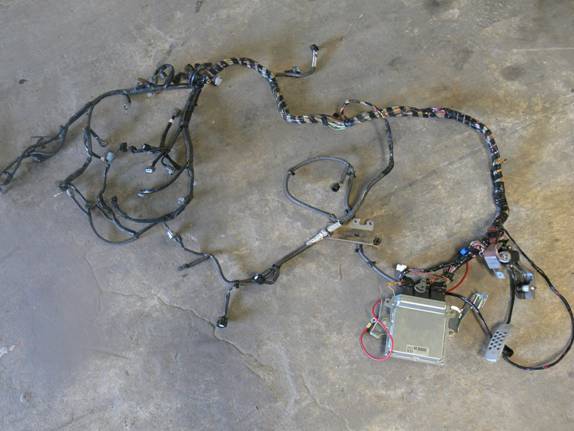

Now for the toughest problem to tackle: how to get the engine to fire up and run. We have taken all the guess work out of it for you. We use a complete stand alone fuel management system. AEM makes one of the best FMU’s (Fuel Management Unit) on the market today. They are extremely comprehensive and tunable. You can do anything and run anything with the AEM FMU. It takes the place of the factory ECU. You won’t need it at all. It is completely stand alone. You will need the factory EFI (Electronic Fuel Injection) wiring harness from the donor car although you won’t need all of it. We convert the factory EFI harness to a plug-and-play harness that plugs right into the AEM and then plugs into all of the VQ35DE’s injectors and many of its sensors. We will then provide you with a start up fuel map to upload to the AEM FMU computer. With this fuel map the engine will fire up. You will then need to tune the car properly based on your particular application (normally aspirated, turbo charged, supercharged, size injectors, etc…). Expect to spend 6-8 hours on a dyno tuning the car properly. The AEM will require a few thing that the VQ35DE motor does not use or is at least different than stock. It needs a 3.5bar map sensor, a coolant temp sensor, an air temp sensor, and a Ford TPS. You will also need to upgrade the fuel pump. We use the Walbro 255 (255 LPH).

Here are some pics of the sensors and how we install them:

The coolant temp sensor:

The Air Temp Sensor:

We install the map sensor into the air pipe in front of the Throttle body but after the air filter.

The last couple things that need to be addressed are the steering shaft, the rack-n-pinion, the speedometer, and the clutch slave cylinder. The steering rack-n-pinion will have to be rotated slightly to clear the factory exhaust manifolds. The steering shaft U-joint will have to be ground away slightly to improve clearance. Here is a picture of the finished product

:

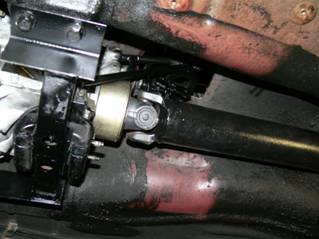

The clutch slave cylinder will have to be moved to the driver’s side of the car in order to bolt onto the OEM position for eth 350Z. We wrap the line in heat wrap because it comes very close to the driver’s side exhaust manifold.

Here is a picture:

The speedometer is driven from a pinion gear on the 240SX’s transmission. The 350Z’s speedo is driven by a signal developed by the ABS brake system and goes through several ECU’s before making the needle move. What we do is buy the differential assembly from an S15 chassis. The S15 Silvia was only available in Japan. It is a bolt-in diff for the 240SX and it utilizes a speedo pinion to drive the speedo on the S15. Just wire it in and you have a speedometer.

From here you need to make some custom radiator hoses, a Y-Pipe to mate the twin exhaust manifolds to you single exhaust system, some heater hoses, electric cooling fans on you factory 240SX radiator, install the Walbro 255 fuel pump and wire up the relays that we can provide with our wiring harness service for the AEM and your EFI. And turn the key!

Approximate costs:

VQ35DE engine -used $2300

6-spd manual transmission –used $750

Bolt-in swap kit $1200 + $200 core fee (we need your X-member back)

AEM ECU w/ UEGO controller built in – new $2300

AEM 3.5 bar MAP sensor and harness $194

AEM air temp sensor $58

AEM coolant temp sensor $40

Ford TPS switch $65

Ford TPS switch harness $42

Custom driveshaft –new $450

Wiring harness service $500

Relays and wiring harnesses $65

Rubber engine mounts (2) - @ $60 each

75mm aluminum throttle body $250

Custom Throttle body pipe $125

FAL dual electric fans $349

SPEC stage 3 perf clutch $659 optional

SPEC aluminum flywheel $429 optional

Fever Racing N1 style stainless exhaust system $359

Fever Racing polished upper plenum $250

Professional installation provided by Z-Fever, Inc $1800 + $600 for tuning.

Additional information regarding wiring harness service of Fever Racing's VQ35 Swap:

In the late 90's Nissan, as did all other automobile manufacturers, was moving towards new solutions to auto theft problems in the USA. One of the ways they did this was to add security programming into the ECU (Electronic Control Unit) that runs the engine. It used to be for the engine only but as technology improved so did the processing ability of the ECU or "computer". The modern ECU's control nearly every aspect of the car''s electronics. All types of systems are controlled in some way by the ECU. Nissan uses a CAN-BUS system that basically takes all the data coming into the ECU for the gauges and then turns that info around and sends it to the gauges. Things like water temp, oil pressure, speed, and tach signal are all sent from the ECU to the gauges. They no longer are directly linked to the engine's sensors or to the transmission for speed reading. In fact, the new transmissions don't even have speed sensors on them. The ABS (Automatic Brakes Control System) has sensors at all 4 corners that send readins to an ABS control unit and to the ECU. The ABS control unit takes this square wave signal and calculates it's ratio and from that generates the actual speed of the vehicle.

Nissan's security system that is built into the ECU is called NATS (Nissan Anti-Theft System). It is an advanced multi-random code hopping alarm system with anti-towing sensors, high-powered siren and electronic override touch key. They can be deactivated by a plug-in dongle, touch key, card, but most modern cars have a chip built into the key that is programmed to your vehicle that says you can start the car with it. Any other key, whether it fits the door or ingition, and does not have this gadget will not work. In the 03+ Nissan line-up of vehicles the ECU must see this signal but so does the IPDM (Intelligent Power Distribution, Module), the BCM (Body Control Module), and the NATS control module. What this means is that if you want to run a Nissan VQ35DE engine into other type of car (like a 240SX or 240Z) you will need to have the ignition key, ignition switch, FM Antenna modulator, the NATS module, the IPDM, the BCM, the ECU, and all the wiring harnesses to each of these (almost every harness in the car) and they all have to be taken from the same donor car. Then you need to wire them all into the car you are building. That is a LOT of work!

All of these components are looking for the same key code and are linked together. If any one of them does NOT see the code from the uniques key then the engine WILL NOT START! That prevents people from stealing cars but it also prevents us tuners from easily transplanting the powerful VQ35DE engine into our tuner cars.

Until now, the only other solution was to buy an expensive stand alone system like the AEM fuel manegement ECU system. They run around $2000 for the base ECU. Then you will need to buy the map sensor, coolant temp sensor, air temp sensor, and figure out how to wire the ECU up to the VQ's EFI harness. Then you need to make a custom intake pipe that you can atatch a cable driven throttle body (TB) because the newer cars are all "Drive By Wire". Which means the TB is electronic and is controlled by the stock VQ's ECU. The newer TB's have step motors on the side of them that open and close when they receive variable voltage signals from the electronic accellerator pedal (shown below)

350Z accelerator pedal assembly:

In the late 90's Nissan, as did all other automobile manufacturers, was moving towards new solutions to auto theft problems in the USA. One of the ways they did this was to add security programming into the ECU (Electronic Control Unit) that runs the engine. It used to be for the engine only but as technology improved so did the processing ability of the ECU or "computer". The modern ECU's control nearly every aspect of the car''s electronics. All types of systems are controlled in some way by the ECU. Nissan uses a CAN-BUS system that basically takes all the data coming into the ECU for the gauges and then turns that info around and sends it to the gauges. Things like water temp, oil pressure, speed, and tach signal are all sent from the ECU to the gauges. They no longer are directly linked to the engine's sensors or to the transmission for speed reading. In fact, the new transmissions don't even have speed sensors on them. The ABS (Automatic Brakes Control System) has sensors at all 4 corners that send readins to an ABS control unit and to the ECU. The ABS control unit takes this square wave signal and calculates it's ratio and from that generates the actual speed of the vehicle.

Nissan's security system that is built into the ECU is called NATS (Nissan Anti-Theft System). It is an advanced multi-random code hopping alarm system with anti-towing sensors, high-powered siren and electronic override touch key. They can be deactivated by a plug-in dongle, touch key, card, but most modern cars have a chip built into the key that is programmed to your vehicle that says you can start the car with it. Any other key, whether it fits the door or ingition, and does not have this gadget will not work. In the 03+ Nissan line-up of vehicles the ECU must see this signal but so does the IPDM (Intelligent Power Distribution, Module), the BCM (Body Control Module), and the NATS control module. What this means is that if you want to run a Nissan VQ35DE engine into other type of car (like a 240SX or 240Z) you will need to have the ignition key, ignition switch, FM Antenna modulator, the NATS module, the IPDM, the BCM, the ECU, and all the wiring harnesses to each of these (almost every harness in the car) and they all have to be taken from the same donor car. Then you need to wire them all into the car you are building. That is a LOT of work!

All of these components are looking for the same key code and are linked together. If any one of them does NOT see the code from the uniques key then the engine WILL NOT START! That prevents people from stealing cars but it also prevents us tuners from easily transplanting the powerful VQ35DE engine into our tuner cars.

Until now, the only other solution was to buy an expensive stand alone system like the AEM fuel manegement ECU system. They run around $2000 for the base ECU. Then you will need to buy the map sensor, coolant temp sensor, air temp sensor, and figure out how to wire the ECU up to the VQ's EFI harness. Then you need to make a custom intake pipe that you can atatch a cable driven throttle body (TB) because the newer cars are all "Drive By Wire". Which means the TB is electronic and is controlled by the stock VQ's ECU. The newer TB's have step motors on the side of them that open and close when they receive variable voltage signals from the electronic accellerator pedal (shown below)

350Z accelerator pedal assembly:

The Electronic Throttle Body:

by way of the ECU. In short, when you hit the gas a voltage signal is created. It goes to the ECU, the ECU then accepts that signal and according to the way the ECU is set up it then calculates how much the TB need to open and then sends a voltage signal to the TB. It opens and you take off!!!!

Aftermarket ECU's do not have the drivers in them to control electronic TB's at this time.

Realizing that Nissan has used the VQ35 in 8 different vehicles produced since 2002 and that the VQ35 will be highly sought after in the coming years we set out to figure out how to transplant this engine into older Nissan vehicles. We figured out how to go into the ECU and and maniputalate it and shut off the NATS programming alltogether. Once this is accomplished the ECU will not need signals from the IPDM, BCM, ignition switch, FM modulator, or ignition key. We are able to then rewire the engine's EFI harness and run it directly to the ECU. We will need the accelerator pedal in order to make the "drive-by-wire" TB work. We also like to add to the harness an OBD-II plug so that diagnostics are still available to the end user. We can also tune the ECU through the OBD-II port.

So, this is what we need from you if you would like us to provide you with this harness and NATS removal service:

* The VQ35DE EFI wiring harness

* The VQ35DE ECU (The ECU has to match the harness you are sending us)

* The accelerator pedal from any VQ35DE powered Nissan vehicle (Not a 2.5L, 4.5L, or 5.6L)

* The harness plug to the accelerator pedal you provide us along with 6" of harness (just cut it out of a parts car)

* An OBD-II plug w/6" of harness cut out of any Nissan vehicle 96 and newer

* The EFI wiring harness from your car (The car the VQ35 engine is going into) The OBD-II

Aftermarket ECU's do not have the drivers in them to control electronic TB's at this time.

Realizing that Nissan has used the VQ35 in 8 different vehicles produced since 2002 and that the VQ35 will be highly sought after in the coming years we set out to figure out how to transplant this engine into older Nissan vehicles. We figured out how to go into the ECU and and maniputalate it and shut off the NATS programming alltogether. Once this is accomplished the ECU will not need signals from the IPDM, BCM, ignition switch, FM modulator, or ignition key. We are able to then rewire the engine's EFI harness and run it directly to the ECU. We will need the accelerator pedal in order to make the "drive-by-wire" TB work. We also like to add to the harness an OBD-II plug so that diagnostics are still available to the end user. We can also tune the ECU through the OBD-II port.

So, this is what we need from you if you would like us to provide you with this harness and NATS removal service:

* The VQ35DE EFI wiring harness

* The VQ35DE ECU (The ECU has to match the harness you are sending us)

* The accelerator pedal from any VQ35DE powered Nissan vehicle (Not a 2.5L, 4.5L, or 5.6L)

* The harness plug to the accelerator pedal you provide us along with 6" of harness (just cut it out of a parts car)

* An OBD-II plug w/6" of harness cut out of any Nissan vehicle 96 and newer

* The EFI wiring harness from your car (The car the VQ35 engine is going into) The OBD-II

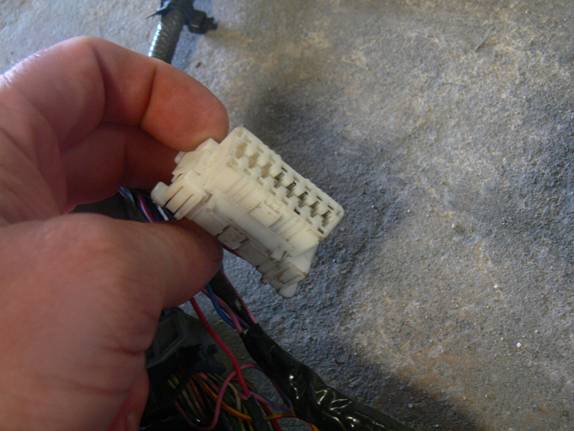

Here is a typical OBD-II plug:

The VQ35DE ECU:

If your ECU has 2 plugs and looks like the one above it is for the VQ35DE. If it has 3 plugs and looks like the one below then it won’t work for the VQ35DE. It is for the VQ35HR.

What we will do is remove the NATS, rewire the EFI harness, add the OBD-II plug, add the accelerator pedal with enough harness to reach the driver's side of the car, and add the dash plug that connects your car's ignition to the ECU so that the engine will start when you turn the key and it will accelerate when you hit the gas pedal. You can now run and drive your car with the VQ35DE engine installed (you are responsible for making it fit into the car obviously).

You still have to contend with the gauges. THIS HARNESS SERVICE DOES NOT RUN YOUR GAUGES!!!!!!!!!!!!!!!!!!!!!!!!!!!

You still have to contend with the gauges. THIS HARNESS SERVICE DOES NOT RUN YOUR GAUGES!!!!!!!!!!!!!!!!!!!!!!!!!!!

The Finished Product:

Note on Engine Swaps

“Due to recent supply chain issues, the global pandemic, and inflation...... prices have gone up on all JDM engine sets. Call for current pricing when you are ready to get the job done. These prices are changing weekly, Thanks for your understanding.”

“Due to recent supply chain issues, the global pandemic, and inflation...... prices have gone up on all JDM engine sets. Call for current pricing when you are ready to get the job done. These prices are changing weekly, Thanks for your understanding.”